▎Products Description

Microporous Diffuser

The novel flat-plate membrane micro-porous diffuser is a mature, reliable, and energy-efficient aerator, primarily used in municipal and industrial wastewater treatment. This product generates small bubbles with uniform diffusion, is highly corrosion-resistant, and features high oxygen utilization, low energy consumption, high efficiency, and a long service life.

The novel flat-plate membrane micro-porous diffuser is a mature, reliable, and energy-efficient aerator, primarily used in municipal and industrial wastewater treatment. This product generates small bubbles with uniform diffusion, is highly corrosion-resistant, and features high oxygen utilization, low energy consumption, high efficiency, and a long service life.

|

|

|

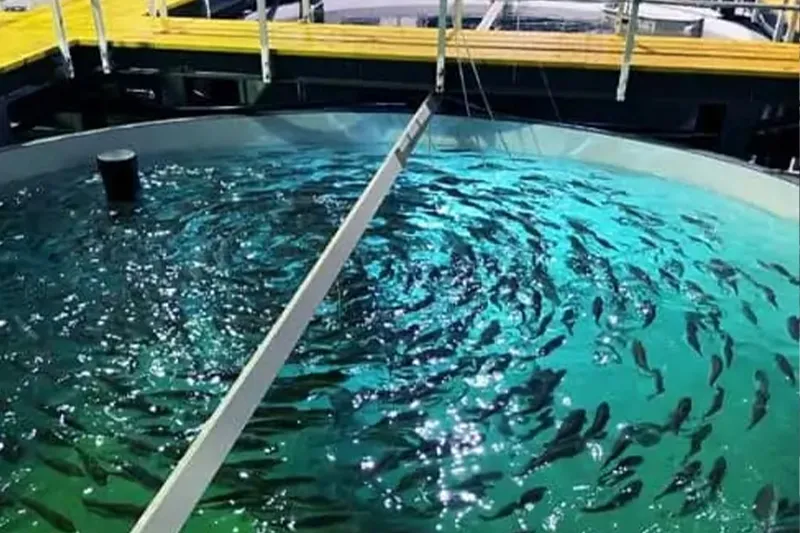

| Integrated equipment | Carp Farming | Integrated Equipment Testing |

|

|

|

| Industrial Sewage Treatment | Recirculating Aquaculture System | Domestic Sewage Treatment |

|

|

|

| Municipal Sewage | Recirculating Aquaculture | Industry Wastewater |

|

|

|

| Electronic Sewage | Artificial Wetland | Integrated Equipment |

|

ltem |

Φ330mm |

|

|

Material |

EPDM |

Silicone Rubber |

|

Service Area |

0.5-1m²/h |

0.5-1m²/h |

|

Number of Holes |

9500 |

6500 |

|

Bubble Diameter |

1-2mm |

1-2mm |

|

Service Life |

>5 year |

>5 year |

|

Aeration Rate |

4-8m³/h |

4-8m³/h |

|

Oxygen Utilization Rate |

235% |

235% |

|

Oxygen Transfer Capacity |

≥0.52Kg/h |

≥0.52Kg/h |

|

Resistance Loss |

≤3500Pa |

≤3500Pa |

|

Hardness (Shore A) |

43 ShoreA |

|

|

Tensile Strength |

14.6 Mpa |

|

|

ltem |

Φ330mm |

|

|

Material |

EPDM |

Silicone Rubber |

|

Service Area |

0.5-1m²/h |

0.5-1m²/h |

|

Number of Holes |

9500 |

6500 |

|

Bubble Diameter |

1-2mm |

1-2mm |

|

Service Life |

>5 year |

>5 year |

|

Aeration Rate |

4-8m³/h |

4-8m³/h |

|

Oxygen Utilization Rate |

235% |

235% |

|

Oxygen Transfer Capacity |

≥0.52Kg/h |

≥0.52Kg/h |

|

Resistance Loss |

≤3500Pa |

≤3500Pa |

|

Hardness (Shore A) |

43 ShoreA |

|

|

Tensile Strength |

14.6 Mpa |

|

The membrane aerator consists of several components engineered for optimal performance and durability:

Chassis and Pallets: Constructed from ABS engineering plastics, these parts provide a robust and durable structure for the aerator.

Cloth Membrane: Made of high-quality EPDM (Ethylene Propylene Diene Monomer) or silicone materials, the membrane ensures efficient gas transfer and resistance to wear and tear.

Aeration Device: The core of the system, responsible for dispersing air through the membrane to achieve effective aeration.

Regulator: Controls the airflow, ensuring consistent and efficient operation of the aeration system.

Connectors and Cloth Gas Piping: These components link various parts of the aeration system, facilitating smooth gas flow and integration of different elements.

Pipe Fittings: Includes tees, crosses, elbows, and other necessary fittings, all designed to connect and direct the gas flow within the aerator system seamlessly.

By optimizing these components, the membrane aerator can achieve superior performance in various applications, offering durability, efficiency, and reliable aeration.

1.Small bubble diameter 2.Bubble diffusion uniformity 3.Strong corrosion resistance

The membrane aerator consists of several components engineered for optimal performance and durability:

Chassis and Pallets: Constructed from ABS engineering plastics, these parts provide a robust and durable structure for the aerator.

Cloth Membrane: Made of high-quality EPDM (Ethylene Propylene Diene Monomer) or silicone materials, the membrane ensures efficient gas transfer and resistance to wear and tear.

Aeration Device: The core of the system, responsible for dispersing air through the membrane to achieve effective aeration.

Regulator: Controls the airflow, ensuring consistent and efficient operation of the aeration system.

Connectors and Cloth Gas Piping: These components link various parts of the aeration system, facilitating smooth gas flow and integration of different elements.

Pipe Fittings: Includes tees, crosses, elbows, and other necessary fittings, all designed to connect and direct the gas flow within the aerator system seamlessly.

By optimizing these components, the membrane aerator can achieve superior performance in various applications, offering durability, efficiency, and reliable aeration.

1.Small bubble diameter 2.Bubble diffusion uniformity 3.Strong corrosion resistance

|

|

|

| Production Line | Warehouse | Sample Room |

|

|

|

| Office | Laboratory | Factory |

|

|

|

| Production Line | Warehouse | Sample Room |

|

|

|

| Office | Laboratory | Factory |

▎Send Inquiry

▎Search

▎Category

▎Recommended